At Shandong Aleader Machinery Manufacturing Co., Ltd., we provide high-quality investment casting services for the aerospace industry, delivering precision-engineered components tailored to withstand the extreme conditions of aerospace applications. From turbine blades to structural brackets, our parts are manufactured to meet stringent performance standards and reliability requirements essential for aviation safety.

Our expertise in aerospace component casting spans across key areas, including jet engine components, structural fittings, and landing gear parts. Every part is produced to the highest quality, offering optimal strength, weight efficiency, and dimensional accuracy to meet aerospace industry demands.

Aerospace castings are metal parts created by pouring molten metal – typically high-strength alloys like titanium, aluminum, nickel-based superalloys (Inconel), or specialty steels – into precisely engineered molds. Once solidified and removed, these near-net-shape components form the backbone of critical aircraft and spacecraft structures and systems. Unlike parts machined from solid blocks (which wastes significant material), castings allow for complex, integrated geometries that would be impossible or prohibitively expensive to make any other way.

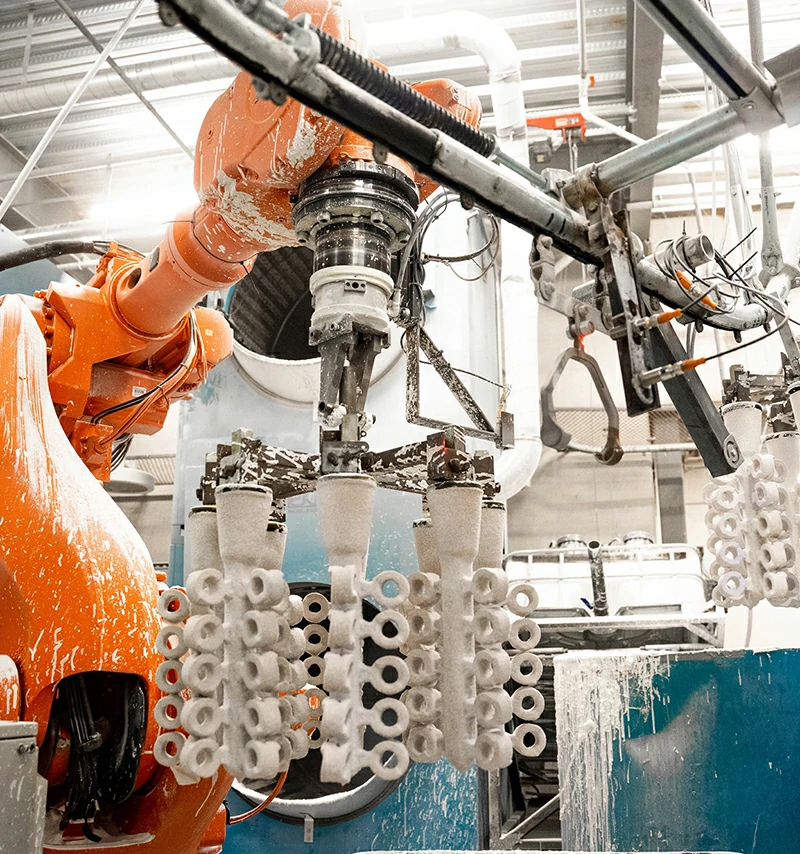

Investment casting plays a pivotal role in the aerospace industry, allowing for the production of high-performance parts that meet critical safety and functionality standards. Collaborating with Aleader ensures added benefits like engineering support, manufacturability analysis, and rapid prototyping, enhancing both design and performance.

Aerospace applications require components that are both strong and lightweight to maximize efficiency and reduce fuel consumption. Investment casting allows for the use of lightweight, high-strength alloys, delivering components that optimize aircraft performance without compromising durability.

Investment casting enables the creation of intricate shapes that are crucial for aerospace parts, such as turbine blades and cooling fins. These complex geometries improve airflow, reduce drag, and enhance fuel efficiency, supporting the advanced aerodynamics required in the aerospace industry.

The flexibility of investment casting accommodates a wide range of specialized materials suited for aerospace applications. From superalloys to titanium, we can cast materials that provide strength, heat resistance, and corrosion resistance, essential for high-stress and high-temperature environments.

Aerospace components must withstand intense forces, extreme temperatures, and challenging conditions. Investment casting produces high-integrity parts capable of withstanding these demands, making them reliable under rigorous conditions.

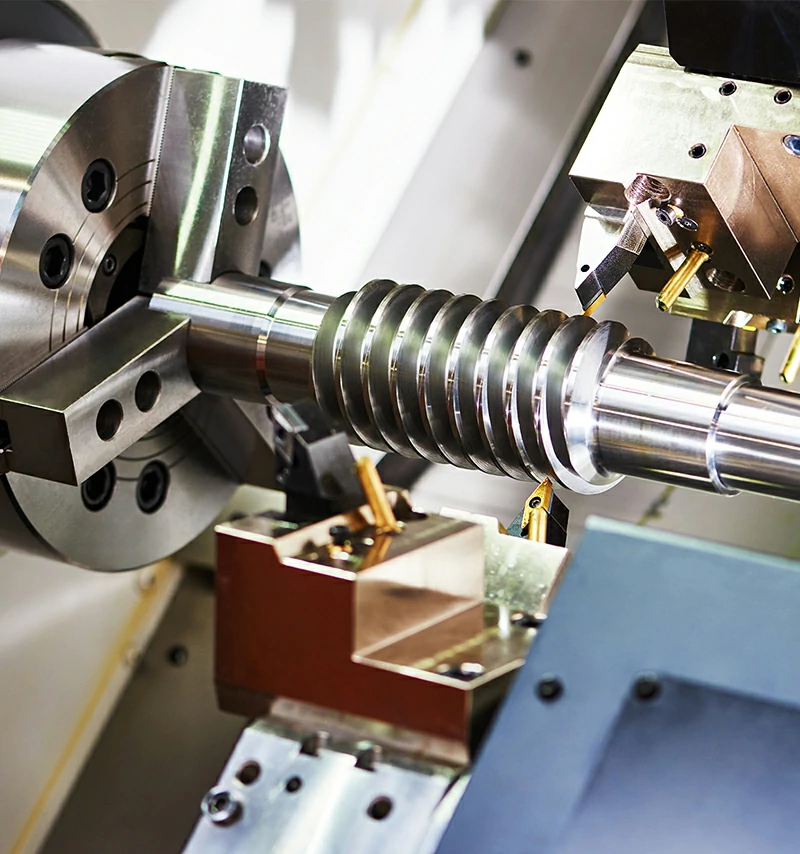

The aerospace industry demands extremely tight tolerances and precise dimensions. Investment casting ensures accuracy and consistency, which is vital for components such as engine parts, where even minor deviations can affect performance and safety.

We adhere to the highest quality control standards, ensuring that every aerospace component meets industry certifications and regulations. Quality is critical in aerospace, where reliability and safety are paramount. Each part undergoes rigorous testing and inspections before delivery.

Our investment casting services allow for highly customized parts tailored to unique aerospace needs. From specific alloys to design modifications, we ensure that each component meets the exact specifications required for seamless integration into your systems.

Shandong Aleader Machinery Manufacturing Co., Ltd. is ISO 9001-2015 certified and dedicated to producing high-performance castings for the aerospace sector. Our commitment to close tolerances and precise finishes ensures that each part aligns with the stringent demands of aerospace engineering.

Choosing Shandong Aleader Machinery Manufacturing Co., Ltd. as your aerospace casting partner means gaining access to advanced manufacturing techniques, exceptional material quality, and a dedication to safety and precision. Our experience in producing components for high-stakes environments ensures that every part we deliver is crafted for reliability and endurance, supporting the critical performance needed in the aerospace industry.