Why is “protective coating” essential for castings?

Castings as the core components of industrial manufacturing, often facing corrosion, wear and tear, high temperature oxidation and other challenges. Powder coating is like putting on an “invisible armor” for castings - through the principle of electrostatic adsorption of powder uniformly covering the surface, after high temperature curing to form a dense protective layer, both anti-corrosion, wear-resistant, beautiful three functions.

Analogous case: like a cell phone film, the powder coating guards the casting with micron-level precision, so that its life expectancy under harsh working conditions is increased by 3-5 times.

Powder Coating Technology: Principles and Advantages

1.Powder coating vs traditional spray painting

Environmental protection: no solvent volatilization, VOC emission close to zero, in line with the trend of green manufacturing.

Efficiency: powder recovery rate up to 95%, cost reduction of 30%.

Performance: Uniform coating thickness (50-100μm), impact strength increased by more than 40%.

2.Core process classification

Cold spraying: room temperature operation, relying on physical adsorption, suitable for small precision parts.

Thermal spraying: high temperature molten powder, stronger bonding, suitable for heavy duty parts.

Powder coating process reveal the whole process

1.Pre-treatment: “deep cleaning” of castings

Steps: degreasing (high-pressure water gun + ultrasonic) → pickling (to remove the oxide layer) → phosphating (to enhance adhesion).

Industry pain point: If the pretreatment is not thorough (such as only drawing treatment), the adhesion decreased by more than 50%, easily lead to coating flaking.

2.Electrostatic spraying: the combination of technology and art

Equipment: Electrostatic spray gun (voltage 60-90kV) with automatic control to ensure uniform powder adsorption.

Innovative design: for wide multi-piece castings, the upper and lower bidirectional spray gun layout is adopted to overcome the problem of powder coating in narrow space.

3.High-temperature curing: the “ultimate finalization” of the coating.

Parameter: Bake at 160-210℃ for 20-30 minutes to form cross-linked polymer structure.

Failure case: due to the curing temperature deviation of 10 ℃, resulting in a sudden drop in the salt spray resistance of the coating, rework costs more than 200,000 yuan.

We follow a strict quality control process

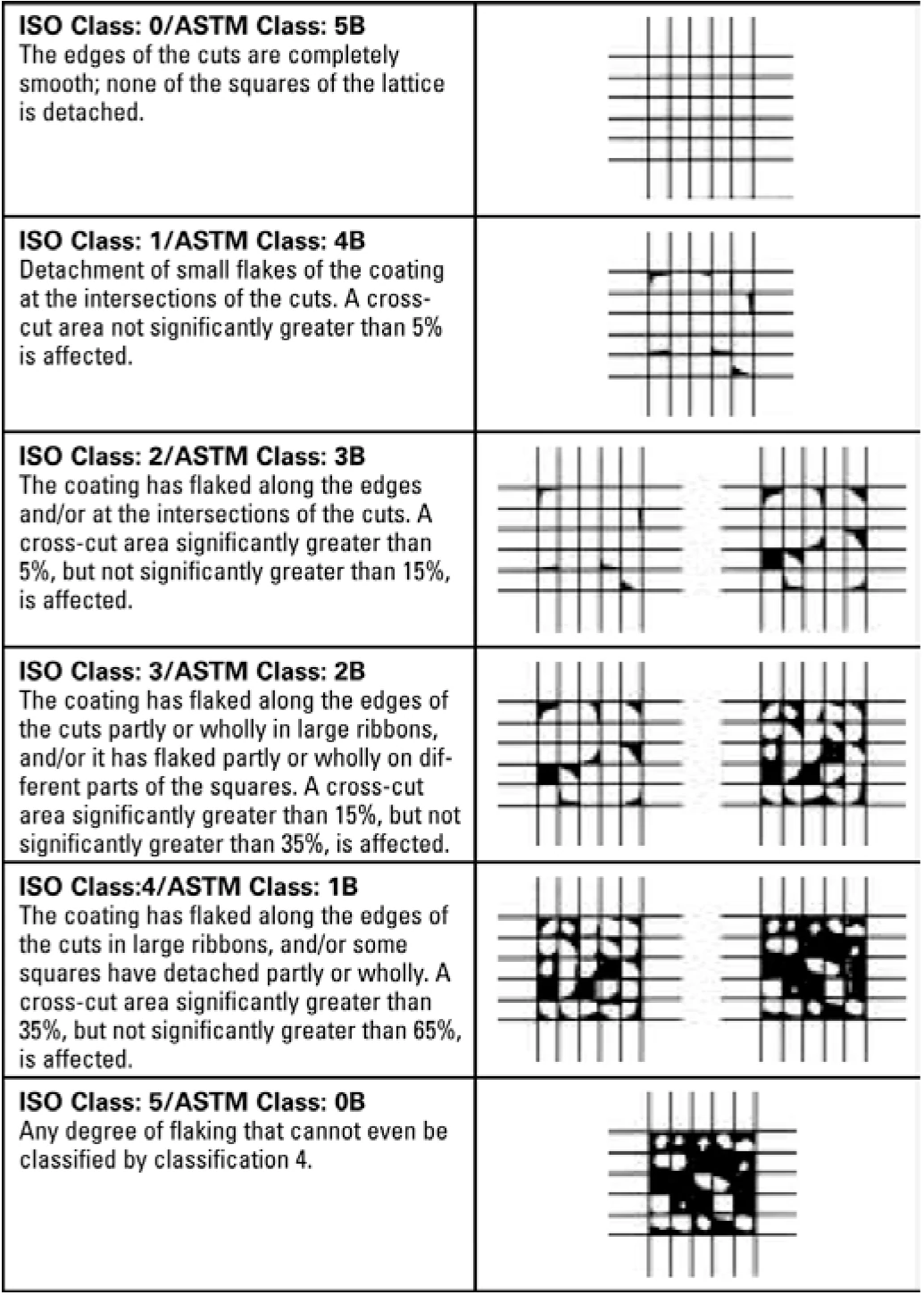

Verification of adhesive properties

Cross Cut Testing (in accordance with ASTM D3359)

Grid Cutting Technique: A precision tool is used to cut a 1 mm x 1 mm (0.04 in.) orthogonal grid on the coated surface to simulate surface stress distributions in everyday use.

Peel Strength Verification: 3M™ Standard Test Strips (ASTM designation) are quickly peeled at 90 degrees and the peeled area is calculated by microscopy.

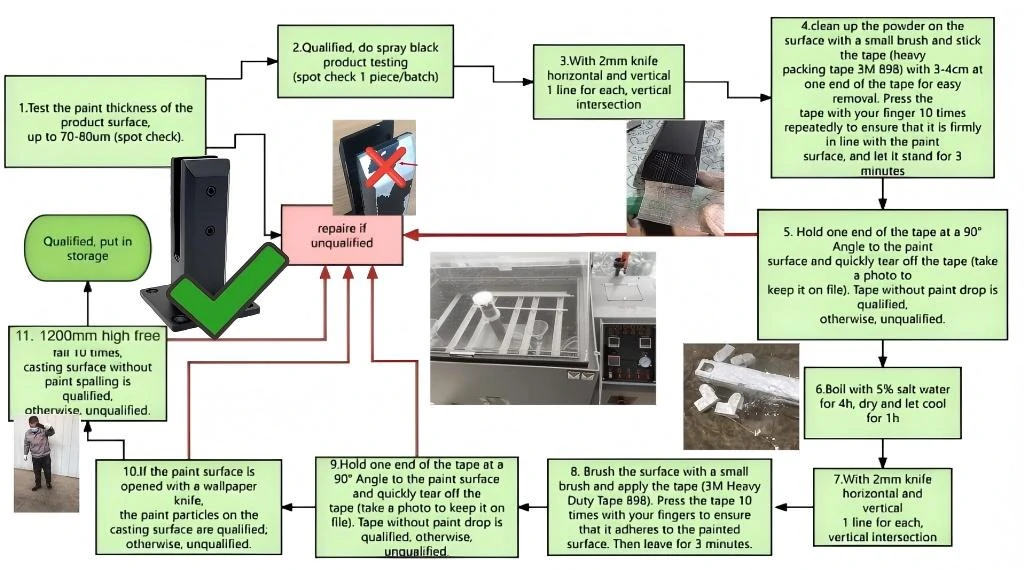

Quality Inspection Process of Black Spraying Products of Aleader Machinery Manufacturing Co.

In order to ensure the stability and reliability of the black spraying product paint quality, the process covers the production operation, quality inspection and division of responsibility for the whole process, aiming at standardized operation to ensure product quality. The following is a detailed description of the specific quality inspection process:

Testing methods and standards

The quality inspection contains two core testing items, both of which are quantitative standards to ensure the objectivity of the results:

Nine grid adhesion test

Definition: In the paint surface delineated nine-grid area, through the grid cutting method to test the adhesion strength of the paint layer and the substrate.

Tools: Specialized grid cutting tool, 3M 898 heavy duty packaging tape.

Judgment standard: After tearing off the tape, the paint surface should be less than 5% of the area to be qualified.

1200mm free fall impact test

Definition: Simulate the natural fall of the product from a height of 1.2meters to assess the impact resistance of the paint and the overall structural stability.

Judgment standard: no cracking, peeling or obvious deformation of the paint surface.

QC Operation Procedure

Step 1: Surface pretreatment

After the production department completes the black spraying operation, it is necessary to use a soft brush to remove the residual dust on the surface of the product to ensure that the inspection area is clean and free of impurities.

Step 2: Tape Pasting and Adhesion Testing

1.Take 3M 898 Heavy Duty Packaging Tape, leave 3-4cm at one end as a tearing handle, and apply the tape flatly to the paint surface. 2.

2.Apply even pressure with fingers along the surface of the tape and press repeatedly 10 times to ensure that the tape is in full contact with the paint surface.

3.After 3 minutes, remove the tape at an even speed at an angle of 60° and observe how the paint comes off.

Step 3: Impact resistance test

Place the product on a 1.2-meter-high fixed platform and free-fall onto a hard surface (e.g., concrete or steel plate) to visually inspect the paint surface and structural damage.

Step 4: Record and Feedback

QC Section will record the test data into the quality management system:

Qualified products: Mark the test number and transfer to the next process.

Non-conforming products: isolate and mark and feedback to production department for rework, engineering department analyze the reason and optimize the process synchronously.

Quality control builds trust, innovation leads to the future

Every powder coating casting needs to pass more than 20 strict control indicators. We promise to guard the foundation of industry with the power of science and technology, so that every casting can stand the test of time.