Heat treatment is a crucial process technology in materials science and engineering, where the physical and mechanical properties of materials are optimized by controlling the heating and cooling processes to meet a variety of industrial needs. Whether in automotive, aerospace or electronic equipment manufacturing, heat treatment plays an important role. In this paper, we will discuss the basic principles, main technologies, and industrial applications of heat treatment, and analyze its future development trend by combining the latest research results.

The basic concept of heat treatment and process classification

What is heat treatment?

Heat treatment is a process that regulates the properties of a material by controlling its heating and cooling processes and changing its internal microstructure. Its goals include enhancing hardness, improving toughness, optimizing corrosion resistance, etc., to support specific uses of the material.

The main processes of heat treatment

Annealing: slow cooling to reduce the hardness of the material and improve ductility.

Hardening: Rapid cooling to increase hardness, but increases brittleness.

Tempering: Reheating after quenching to reduce brittleness while maintaining hardness.

Normalizing: Air cooling improves the uniformity and mechanical properties of the material.

Anatomy of a Scientific Principle

During heat treatment, the microstructure of the metal undergoes phase changes, such as the transformation from austenite to martensite, which directly affects the material properties. In addition, diffusion mechanisms play an important role in the uniform distribution of elements and microstructure optimization.

Industrial applications of heat treatment technology

Central role in the steel industry

Steel is one of the most widely used materials for heat treatment applications. In the automotive industry, heat treatment enhances the strength and impact resistance of steel plates; in the field of bridges and construction, structural safety is ensured by optimizing hardness and toughness.

Innovative applications in non-ferrous metals

Aluminum alloys: Strength and corrosion resistance of aerospace components are enhanced by age strengthening.

Titanium alloys: heat treatment technology for medical implants not only enhances mechanical properties but also improves biocompatibility.

Heat Treatment of Specialty Materials

Nickel-based high-temperature alloys are widely used in gas turbines and chemical equipment because of their excellent performance in high-temperature and corrosive environments. Through heat treatment, the organization of these alloys is further optimized, resulting in longer service life.

Academic Frontiers and Latest Research

Frontier Science: Emerging Technologies in Heat Treatment

Laser heat treatment: Utilizing laser to precisely control temperature and improve surface properties.

Plasma Heat Treatment: Enhancement of surface hardening effect through plasma while reducing environmental impact.

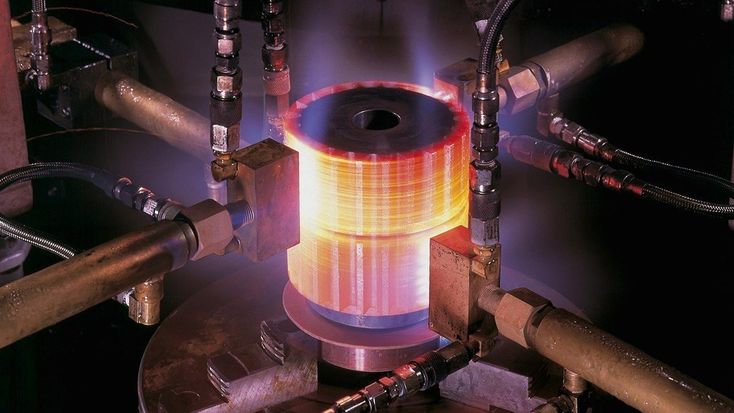

Induction Heat Treatment: Highly efficient heating technology, especially suitable for parts with complex shapes.

Abstracts of Important Papers

Yilbas, B. S., et al. (2021)

Research: Microscopic mechanisms of surface hardness enhancement of steel alloys by laser heat treatment.

Results: Enhanced uniformity of microstructure and improved wear resistance.

Zhang, X., et al. (2023)

Research: Influence of quenching medium on residual stress distribution in high carbon steel.

Results: The quenching process was optimized and the possibility of crack generation was significantly reduced.

Expansion of science: Heat treatment in daily life

Strengthening treatment of stainless steel kitchenware

Through heat treatment, stainless steel kitchenware is widely used in daily life by enhancing corrosion resistance while maintaining high hardness.

Heat treatment applications in cell phones and electronic devices

Aluminum for smartphone housings and heat dissipation components undergoes a precise heat treatment process to provide greater durability and heat dissipation efficiency.

Conclusion

As a cornerstone technology of modern industry, heat treatment plays an irreplaceable role in optimizing material properties. In the future, with the deeper application of automation and digitalization, the heat treatment process will become even more efficient and environmentally friendly, opening up more possibilities for industry and scientific research.