Numerical Control Machine Tools: Micron-Level Precision Engineering

CNC (Computer Numerical Control) machine tools have revolutionized manufacturing with their unparalleled precision engineering and micron-level accuracy. They are critical in industries like aerospace, healthcare, and electronics, where strict tolerances are required. In this article, we will explore the science behind CNC machining, share practical applications, and delve into academic research highlighting its technological advancements.

What Makes CNC Machines Unique?

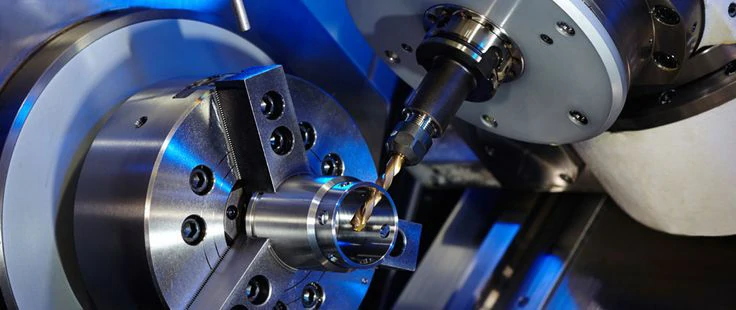

CNC machines are designed to achieve dimensional accuracy, even for complex geometries, with precision measured in microns (1 micron = 1/1000 mm). By leveraging technologies such as multi-axis machining, adaptive control systems, and real-time monitoring, they ensure the repeatability and consistency of every manufactured part.

Key Concepts in Precision Machining:

Strict Tolerances: CNC machines can achieve tolerances as low as ±5 microns, which is crucial in aerospace, medical devices, and electronics.

Micron-Level Precision: CNC machines produce parts with micron-level accuracy, ensuring even the smallest parts fit perfectly into larger assemblies.

High-Speed Spindles: Equipped with high-speed spindles, CNC machines enhance the machining process by increasing material removal rates while maintaining accuracy.

Multi-Axis Machining: Multi-axis CNC machines (e.g., 5-axis machining) create complex geometries that are challenging or impossible with traditional methods.

Surface Finish Optimization: Achieving the desired surface finish (often defined by Ra values) is critical for applications in medical, aerospace, and automotive components. CNC machining provides tools and techniques for smooth, polished surfaces.

Repeatability and Consistency: CNC machines can perform the same machining operations with high consistency, ensuring every part produced has identical shape and dimensions.

The Science Behind CNC Precision Machining

The precision of CNC machines is driven by the integration of hardware, software, and innovative manufacturing techniques. Below are some key technologies that enable precision machining and allow CNC machines to meet strict tolerances and micron-level accuracy.

1. High-Speed Spindles and Material Removal Rates

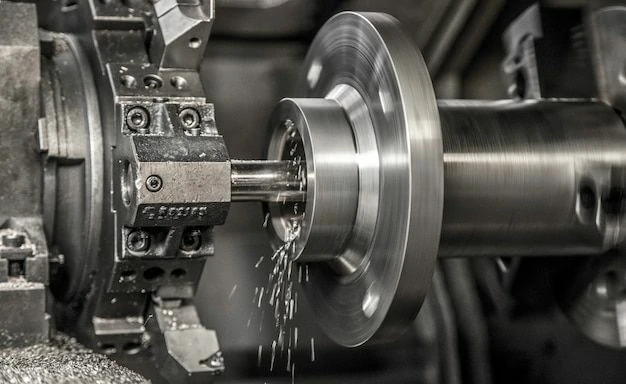

High-speed spindles allow for faster cutting speeds, enabling the machine to remove material at higher rates while maintaining accuracy. These rates are crucial for machining harder materials like titanium, composites, and ceramics, commonly used in aerospace and medical industries.

2. Thermal Stability and Compensation

Thermal effects can alter the dimensions of the machine and workpiece, affecting final product accuracy. CNC machines use thermal stabilization systems (including cooling mechanisms and thermal compensation algorithms) to minimize temperature-induced variations.

3. Multi-Axis and Complex Geometry Machining

A significant advantage of CNC machining is the ability to work with multi-axis machines, which can move tools along multiple axes simultaneously. This allows CNC machines to machine complex geometries (e.g., curved surfaces, deep holes, and intricate patterns) that are impossible with traditional methods.

4. Adaptive Control Systems and Real-Time Monitoring

Adaptive control systems optimize machining processes in real-time by monitoring key variables such as tool wear, temperature, and cutting forces. These systems dynamically adjust parameters like feed rate and spindle speed to maintain precision and avoid deviations.

5. Automatic Tool Change and Precision Control

Modern CNC machines feature automatic tool changers that quickly and efficiently switch tools during machining. This minimizes downtime and ensures precision throughout the process.

Applications of Precision Machining

Precision machining is utilized across industries that demand high-quality components with exacting standards. CNC machine tools are essential for achieving the tight tolerances and micron-level accuracy these applications require.

1. Aerospace Industry

CNC machining is critical in producing aerospace components like turbine blades, fuselages, and structural parts requiring dimensional accuracy and the ability to withstand extreme conditions. High-performance cutting tools and multi-axis machining are essential for achieving complex geometries and precision.

2. Medical Devices and Implants

In medical device manufacturing, surface finish optimization and tight tolerances are essential for ensuring biocompatibility and functionality. Precision machining is used to create prosthetics, joint replacements, and surgical instruments, where even small deviations can result in failure.

3. Electronics and Semiconductor Manufacturing

As electronic devices grow smaller and more complex, components like connectors, circuits, and chips require micron-level precision. CNC machines help produce precise micro-components with intricate geometries, meeting the high standards of the electronics industry.

4. Automotive and Industrial Equipment

The automotive and industrial equipment industries rely on CNC machining to produce high-precision engine parts, gear assemblies, and robotic arms. High material removal rates are necessary when machining tough materials like high-strength alloys and carbon composites.

5. Non-Traditional Material Machining

CNC machines expand the scope of precision machining by processing non-traditional materials like ceramics, composites, and advanced polymers. These materials require advanced cutting techniques and specialized tools for effective machining.

The Future of CNC Precision Machining: Trends and Innovations

As demand for micron-level precision continues to grow, the future of precision machining lies in the development of more advanced technologies and materials.

1. Nanometer-Level Accuracy

CNC machines are advancing toward achieving nanometer-level precision, enabling the production of nano-scale components critical for nanotechnology and biotechnology industries.

2. Artificial Intelligence and Machine Learning in CNC

Integrating AI and ML into CNC machines will foster the development of adaptive control systems capable of predicting and adjusting machining parameters in real-time, further enhancing precision.

3. Sustainable Manufacturing

With global efforts toward sustainability, energy-efficient CNC machines and zero-waste manufacturing will gain more focus. These innovations will optimize energy consumption and reduce environmental impact while maintaining precision.

Conclusion: The Future of Precision Machining

CNC machines continue to drive innovation in precision machining, delivering micron-level accuracy, strict tolerances, and complex geometries across industries. With advancements in high-speed spindles, multi-axis machining, and real-time monitoring, CNC machines can manufacture more intricate, high-performance components. As AI, adaptive control systems, and nanometer-level precision become more prevalent, precision machining will evolve to push the boundaries of modern manufacturing.

Recommended Reading:

International Journal of Advanced Manufacturing Technology: "AI and Adaptive Control in CNC Machining"

Journal of Precision Engineering: "Enhancing Dimensional Accuracy in CNC Machines"

CIRP Annals: "Multi-Axis CNC Machining: Features and Applications Review"