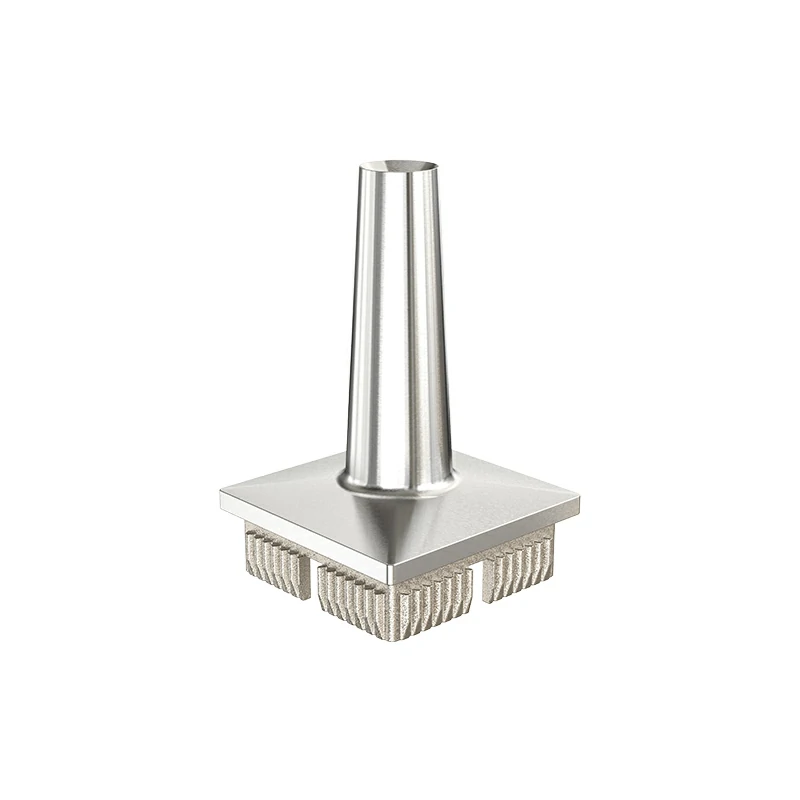

Handrail Support Description

Stainless steel handrail support bracket is crucial components for securely mounting handrails to walls, posts, or other vertical surfaces. Handrail Support Brackets come in various sizes, and designs to accommodate different handrail styles and installation requirements. They are engineered to provide a secure attachment point for the handrail while enhancing the overall design of the space. These handrail brackets play a critical role in supporting and securing handrails along staircases, balconies, decks, or other areas where handrails are necessary for safety and functionality.

Handrail Support Brackets are made of high-quality stainless steel, due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel is well-suited for both indoor and outdoor applications as it can withstand various environmental conditions.

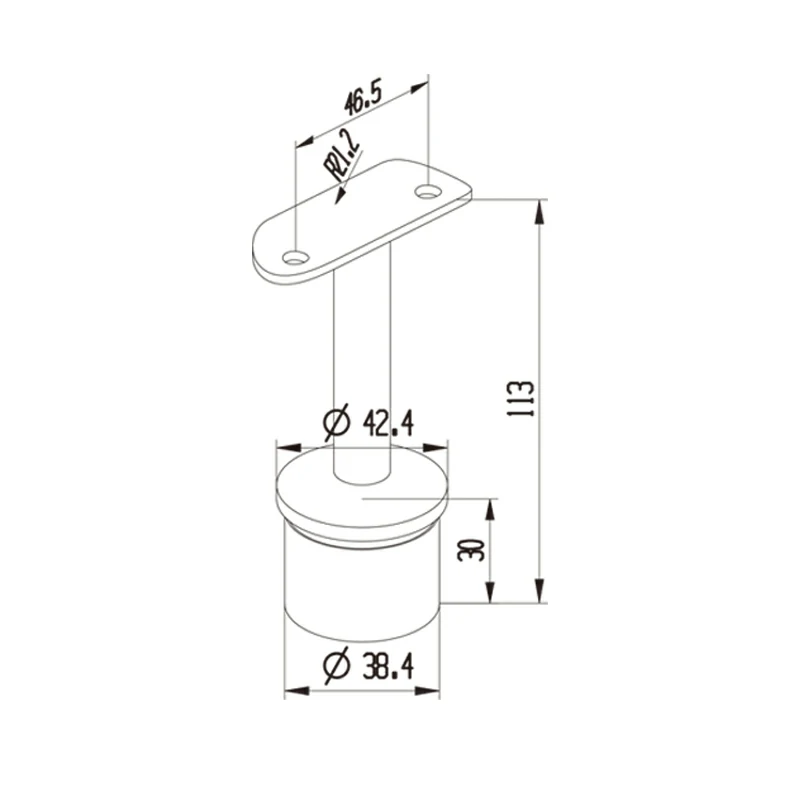

Handrail Support Specifications

|

Product Name |

Handrail Bracket |

|

Coupling |

Φ42.4mm |

|

Weight |

0.20Kg |

|

Finish |

Classic Satin/Mirror Powder Coat Matte Black/White PVD-Black/Gold/Rose Gold/Gun Grey Anti-conductive Black/White Transparent Satin/Mirror |

|

Material |

Duplex stainless steel 2205, Stainless steel 304/316 |

|

Application |

Suitable for all kinds of indoor and outdoor handrails and balustrades, etc. |

|

Casting Process |

Silica Sol Technics with Lost-wax Process |

|

Certifications |

Australian Standard Test/Patent Certificate/IATF16949/ISO9001/ISO14001/TUV/PED/AD2000 |

|

OEM |

Available |

|

Annual Output |

2000MT |

|

Tooling Leadtime |

2--4 Weeks |

|

Delivery Time |

4--5 Weeks |

Package Specification

Plastic Bag, Bubble Bag.

Paper Carton, Wooden Case, or as Required.

Note

Stainless steel handrail support brackets are typically installed using screws or bolts to secure them to the wall or post. Proper installation is crucial to ensure the handrail is securely supported and meets safety standards. It is essential to ensure that the Stainless Steel Handrail

Regular cleaning with a mild detergent and water can help preserve the appearance of the brackets. Periodic inspections for any signs of wear, corrosion, or loosening of connections are recommended to maintain the integrity of the handrail support system.